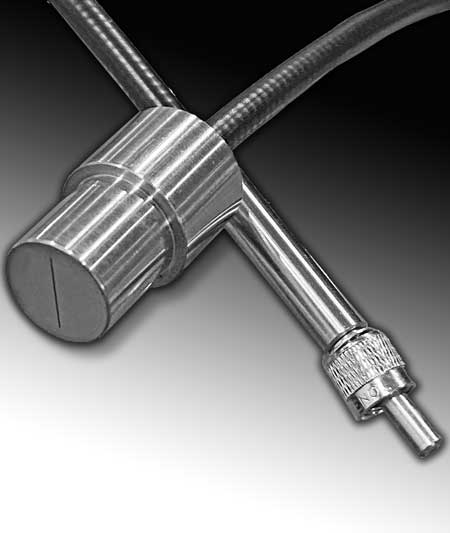

Silica (commonly referred to as quartz) fiber bundle assemblies are photon delivery subsystems consisting of many small individual silica fibers, bundled together and combined in either a custom machine-made ferrule or off-the-shelf connector housings designed for use as end fittings. A heavy-duty bundle sheathing is typically incorporated to protect the bundle assembly from damage during use.

Silica fibers consist of two silica material types, each with a different index of refraction. The core of the fiber is typically made out of pure synthetic silica material, surrounded by a second silica cover. Known as cladding, this second silica type is doped with a material, commonly fluorine, giving the clad silica a lower index of refraction. Taking advantage of a phenomenon known as Total Internal Reflection, this doped silica cladding keeps light inside the core material.

To minimize the chance of scratching the clad, and to support the fiber during bending, all silica fibers include a polymer coating (also known as a buffer). These coating types include polyimide, acrylate, silicone, and hard optical polymer (various formulations exist under this common description).

To complete the package, several fiber configurations also use a second coating referred to as a jacket. Common materials for jacketing include Tefzel, Nylon and Teflon; each with strengths and weaknesses that can be optimized for a particular application.

One specialized silica fiber type uses a polymer material as a clad, substituting for the second silica material, or in addition to the silica clad for high power applications.

Silica fibers are also classified by concentration of Hydroxide, or OH. The specific concentration of OH in silica, in parts per million (ppm), dictates the precise wavelengths of light which that silica fiber can transmit.

High-OH silica fibers, with OH concentrations between 800 and 1,200ppm, are best suited for light with wavelengths between 190 nanometers (nm), in the Deep UV spectrum, and 1,200nm, in the visible spectrum.

Low-OH fibers usually include OH concentrations of 2ppm or less. They are best suited for transmitting light wavelengths of 400nm to 2,500nm in the NIR spectrum. In low-OH fibers, the less OH the better — lower amounts of OH reduce attenuation losses and increases transmission efficiency.

The visible light spectrum is the segment of the electromagnetic spectrum that the human eye can view, typically wavelengths from 380nm to 700nm. Silica fibers are best suited for demanding applications in ultraviolet (UV) (200-380nm) or near-infrared (NIR) (750-2500nm),

wavelength regions where other materials, such as borosilicate glass and thermoplastics, don’t work efficiently.

Silica fiber bundle assemblies are flexible and easy to work with compared to using single, larger fibers, which tend to be very stiff.

Silica fiber bundles are manufactured in a variety of sizes, shapes, lengths, jacket and sheathing types, and configurations (single, bifurcated, trifurcated, and multi-legged). Other variables include OH concentration, individual active diameters (sizes ranging from 50 to 300 microns), numerical aperture ranging from 0.12 to 0.28; up to.48 using hard Polymer Clad silica, randomization, high temperature (as high as 800°C), and vacuum conditions (up 10 -8 Torr).

Silica fiber bundles have no inclusions, are bubble-free, and are highly suited for scientific applications. Bundles made of these fibers offer high homogeneity, low stress birefringence, superior flexibility, and high transmission efficiency. This holds especially true in Deep UV and NIR applications.

Silica bundle assemblies are used in a huge variety of industries, environments, and applications: industrial and medical laser delivery systems, remote spectroscopy, analytical chemistry, particle detection, fluorescence excitation, machine vision, chemical analysis, colorimetry, Raman scattering, Thompson scattering, optical pyrometry, remote illumination, sensors, high temperature and harsh environment sensing, laser welding and soldering, medical diagnostics, flow cytometry, plasma physics, life sciences, biomedical, laboratory, genomics and other DNA studies, astronomy, solar simulation, and for optical/photonic measurement of physical, dynamic, and geometric properties, including temperature, pressure, vibration, vacuum, radiation, distance, and more.