Customized Sterile Barrier Packaging of Fiber Optic Components for Demanding Applications

FTI’s packaging cleanroom represents state-of-the-art design and construction for a Class 7 Cleanroom facility. The room is a hardwall, reconfigurable design, intended to be upsized or adapted quickly should demand or component quantities require it.

The room utilizes continuous monitored, laminar flow, positive pressure air through high efficiency particulate air (HEPA) filters to remove airborne particulate as small as .3 microns.

To assure seal consistency, temperature and humidity will be maintained at optimal levels through a dedicated, room controlled HVAC system, even though the cleanroom itself is already contained within a climate controlled facility.

The cleanroom was designed to support customers in any market who require sterile barrier packaging, with or without sterilization coordinated services.

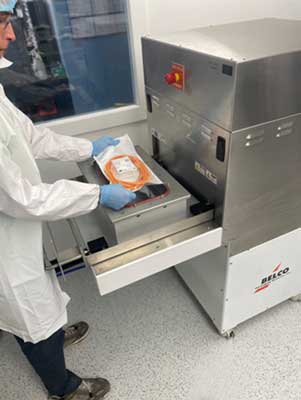

Belco tray and pouch sealers repeatedly produce dependable sterile barrier containers assuring contamination and FOD free components from containment through transportation, receiving and inventory storage until the component is ready for integration or final use. Our seal integrity and visual aesthetics have been rigorously qualified and routinely monitored for each lot produced to maintain integrity.

Our sterile barriers are suitable for Radiation (gamma, x-ray, e-beam) and EO sterilization; an outsourced service we offer when required.

Currently, FTI has a validated process for sealing an 8” x 16” peel pouch, as well as 17” x 8.5” x 2”, and a 15” x 7” x 2” PET-G trays w/ Tyvek lids, suitable for packaging most fiberoptic cables and lighting accessories.

FTI will also work with you to oversee 3rd party accelerated aging and transportation testing for new packaging material or packaging design configurations.