The benign nature and unique advantages of light transmission through optical fiber have led to some unusual applications, from sensing methane gas to flow cytometry.

Because fiber doesn’t use or conduct electricity, optical fiber is already widely used “as a conduit for temperature sensors based on infrared (IR) light.”1 These pyrometers, typically utilized in high-temperature applications, use a fiber extension to pick the emitted IR fr om a heated body so that the sensitive electronics can be kept at a safe distance. This is particularly important wh ere there are high levels of electromagnetic or radio-frequency interference, such as on a factory floor with larger motors or welders.

Of course, much depends upon the fiber’s own operating temperature range and it may need special protection, such as water cooling, if ambient temperatures rise above 900˚F.

Once inside an electrical system, the characteristics of fiber are again useful. It can weave its way in and around electrical components and systems without risking dielectric breakdown. Also, because fiber is non-conductive, there’s no risk of arcing or associated sparks from worn or broken wires. As such, through the use of fiber, the risk of fire or explosions caused by electrical cable faults/shorts is significantly reduced.

Optical fiber is widely used for conveying sensor data, as well as functioning as a sensor for pressure or strain. Additionally, fiber can be used to convey modulated or altered properties of light, such as specific wavelength(s) or polarized light. Still, researchers continue to discover new ways of applying fiber to develop new types of sensing and sensors.

In one such example, optical fiber is being used as a means of detecting methane by measuring the amount of laser light absorbed by the methane. Methane has its own absorption signature, so if there is methane present, the reflected light will contain the signature. The detector can be in a single, portable instrument. Alternatively, a gas monitoring system can use laser light distributed over multiple fibers together to detect gas leaks at multiple points in service tunnels, utility ducts, mines, and unconventional gas operations.2

Using optical fiber as the backbone for sensing applications in off-shore oil or gas rigs also plays into the use of fiber for safe, heat- and electricity-free area and equipment lighting.

Medical instrumentation

We recently spoke of the many areas in which fiber is being applied that even the manufacturers of fiber would not have thought of; many are at the cutting-edge of bio-medical research.

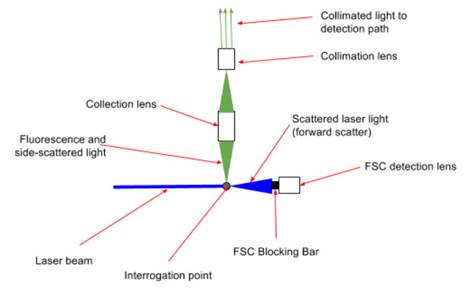

The use of fiber for spectroscopy, where light absorption and reflection is used to identify elements in solids and liquids is well advanced. But many may not be as familiar with flow cytometry. Here, single cells from complex solutions are detected, quantified, and analyzed in a reagent stimulated by lasers. The detector may be a photomultiplier tube (PMT) or a charge-coupled device (CCD), but before the resulting fluorescence or side-scatter light gets to the detector, it must first be gathered with a collection lens, and then routed to the detector, typically using fiber (Figure 1).3

Due to its flexibility, fiber has a big advantage here as it allows the lens to be placed anywhere within the instrument for optimum collection, then small, flexible, reliable fiber can serve as a conduit, this time to the cytometer’s detector. Note that for better coupling, an optical gel is often used as the interface between the lens and the fiber.

As fiber becomes even more integrated, its flexibility, non-electrical-conductive and lightweight nature will continue to play a role in helping designers advance state-of-the-art instrumentation size, cost and portability.

While fiber’s applications vary widely, they can be quite simple too, such as basic absence/presence detection, Here, when used in conjunction with an emitter/receiver sensor, fiber optimizes the ability to detect discrete samples during processing, which assures non-stop analysis and accurate, fool-proof organization of results; yet another good example of optical fiber’s simplicity and utility.