If you’re a fiber optic user, you know that light output is cast as a cone, like a broad beam flashlight. For many applications, this is exactly what’s expected for general illumination.

Sometimes, the application can’t use a broad beam; maybe the user is trying to control the spot size, focus or diffuse the output, or create a clean bright spot. For these circumstances, additional accessories or alternate approaches are taken to provide effective results.

Several Diffuser Types

For applications requiring diffusive outputs, a simple milk glass or plastic diffuser in a housing, attached to the distal end, is effective and economical. If the requirement calls for a shaped diffusive pattern, (circle, line or slit, oval, etc.), a holographic diffuser should be considered. These devices are offered in varying degrees of diffusion and shape. They are both efficient and effective. They are available in a wide array from Luminit, a company specializing in the production of holographic diffusers. For use with fiber optic cables, a holder is created to hold the diffuser, which is attached at the distal end of the light guide.

Lenses Focus Output to a Spot or Column

A simple planoconvex lens attached to the distal end of a light guide will collect the diverging beam, projecting the output in a column; an effective solution for lighting through an opening, or managing stray light, which is dramatically reduced. As it is with diffusers, a housing is designed to hold the lens on the distal end, which can be focused to optimize intensity. You can expect 10x more intensity from the smaller spot, but the spot will also project an image of the fiber bundle when critically focused.

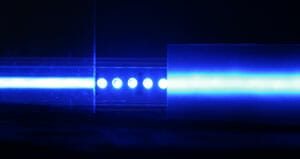

Clad Rod Creates a Perfect Circle of Light

If you need an intense small spot, free of any artifact, insert a clad rod between the fiber face and the lens. This is a neat trick to create a beautiful, bright, clear spot of light. The clad rod moves the fiber face outside beyond the lens’ Back focal length, making it invisible. The lens focuses on the front face of the clad rod, projecting a homogenous beam of artifact-free light. Because the clad rod is also carrying the beam, the only loss is from Fresnel effect (8-10%). This design takes more effort, because the light guide and the clad rod should be polished. Both are assembled in a common housing or separate housings, then joined together.

Use an Iris to Control Spot Size

Finally, if you need to control the size of the spot throughout an application, install an iris. Iris apertures come in a variety of sizes and configurations. Moving a lever on the iris changes the opening from almost closed to almost open continuously throughout the range of operation. A special adapter is created to hold the device on the distal end of the light guide.

Regardless of the approach, make every effort to mount the spot control device on the distal end; doing so offers the most control and the lowest risk of damage caused by heat.