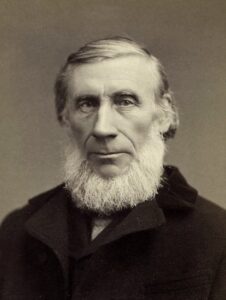

The technology of fiber optics was first identified in the 1870’s when John Tyndall noticed light from a gas street lamp was captured in a stream of water coming from a full barrel of water positioned beneath the light.

However, it wasn’t until the 1950s that a formal method of transmitting light through a glass fiber was realized by Narinder Singh Kapany. In 1960, he wrote a paper describing his experiments and coined the phrase “Fiber Optics”.

His research proved that a glass fiber could contain a light beam as it travelled through glass whether straight or bent, as long as the index of refraction for the glass core was greater than the index of refraction for the media surrounding the glass. This phenomenon is described as a principle of physics called “Total Internal Reflection” (T.I.R).

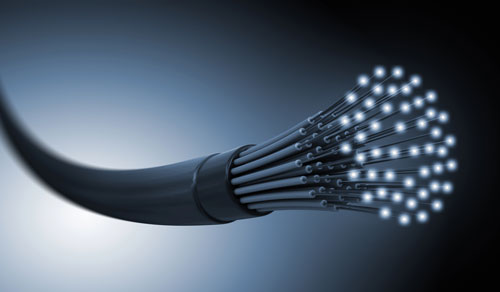

As the light beam bounces around in the glass core, it strikes the glass boundary, which is surrounded by another medium (typically a different type of glass, but it could also be plastic) referred to as the cladding.

If the ratio of refractive indexes for the core and clad are compliant with the physics law, light will bounce off the boundary and reflect back into the glass continuing along a path defined by the light’s entry angle into the glass. If the indexes are not compliant, the light will escape the boundary at that meeting point, and never complete the journey through the core glass.

The index of refraction (I.R) is a measure of the speed of light in any particular medium. Light travels fastest in a vacuum….and so … we can conclude the higher the I.R, the slower the speed of light through a related medium.

In the chart below, you can find some common refractive indexes for “glass” cores and “glass” claddings.

| CORE TYPE | CORE I.R | CLAD TYPE | CLAD I.R |

| Flint Glass | 1.72-1.51 | Borosilicate Glass | 1.48 – 1.56 |

| Silica | 1.45 | Doped Silica* | 1.44-1.47 |

| Fluoride Glass | 1.5 | Air or vacuum** | 1 |

*-Silica glass for cladding is altered with a dopant to lower the refractive index.

**-IR for air is slightly higher (1.0003). For this discussion we treat them the same.

From the chart above, you could conclude the index of the core material MUST be higher than Index of the clad material to produce T.I.R (Total Internal Reflection).

The above is an explanation for Multimode step index fibers, commonly used in lighting applications.

Another type of fiber, known as single mode graded index, is designed for communication fibers.

We will limit our discussion to multimode Step index fibers, because this fiber type is designed for lighting applications, using general light sources in varied configurations.

Knowing what fiber optics is and how it works helps to identify the universe of applications, which you might conclude, is very large.

You should consider fiber optics as a lighting solution under the following general conditions:

- When it removes electricity from the lighting site.

- When heat is a disruptive artifact at the lighting site

- When the environment is hostile to wiring.

- When a spark could casus a fire or explosion.

- When the application requires a special shape of light output (a ring or line of light, for example)

- When it’s difficult or impossible to maintain a functioning light (like at the top of a flag pole, high space, under water, small spaces etc)

- In commercial applications where discrete lighting sources and emitters are important to create a mood.

- Applications requiring tiny point light sources (Smaller than available lamps).

Considering the above scenarios, fiber optic lighting is probably preferred; not only can you put light where you need it, in many circumstances, there are no alternatives.

Surely, fiber optic lighting can be used in other circumstances where traditional lighting is common, however, cost and performance trade-offs negate the value of fiber optics in traditional lighting scenarios.

Fiber optics is much more expensive than wire. The light power going through a fiber optic cable diminishes over distance, and the amount of power available to the fiber optic cable is always (at least) 40% more than what the fiber optic cable captures. You still need an emitting fixture and light source to produce most effects. In comparison, a bulb output is always 100% no matter where you mount it, and only requires 2 wires and an electrical connection.

In summary, there’s nothing as good as fiber optic lighting, but when your application requires it.